INNOVATION IN EVERY DETAIL

Alustage Production Technology

400

skilled professionals

20,000 m²

of production space

100,000 m²

of stage platforms manufactured annually

130 km

of truss systems produced each year

2 million kg

of processed aluminium annually

TÜV, DVS ZERT, and ISO

certified production

ALUSTAGE TECHNOLOGY – INNOVATION IN EVERY DETAIL

What can we create for you?

We specialize in manufacturing truss systems, stage platforms, and professional, complete stage systems — but we’re always ready to take on custom projects tailored to your individual needs. With our state-of-the-art production facilities, we offer comprehensive manufacturing of aluminium, steel, wood, and composite components — from precision cutting and processing to assembly and flawless surface finishing. Whether you need a prototype, a small production run, or full-scale serial manufacturing, we guarantee quality, on-time delivery, and full flexibility.

Click on any link

Navigation menu

A TRUSTWORTHY COMPANY

Advanced Machinery – Our Production Capabilities and Technological Edge

Our state-of-the-art production facilities empower us to deliver even the most demanding projects with precision and efficiency.

1. Realistic 3D Visualizations – Plan Your Production with Confidence

We create detailed 3D models and renderings that streamline project planning and decision-making right from the initial concept. With our visualizations, you can:

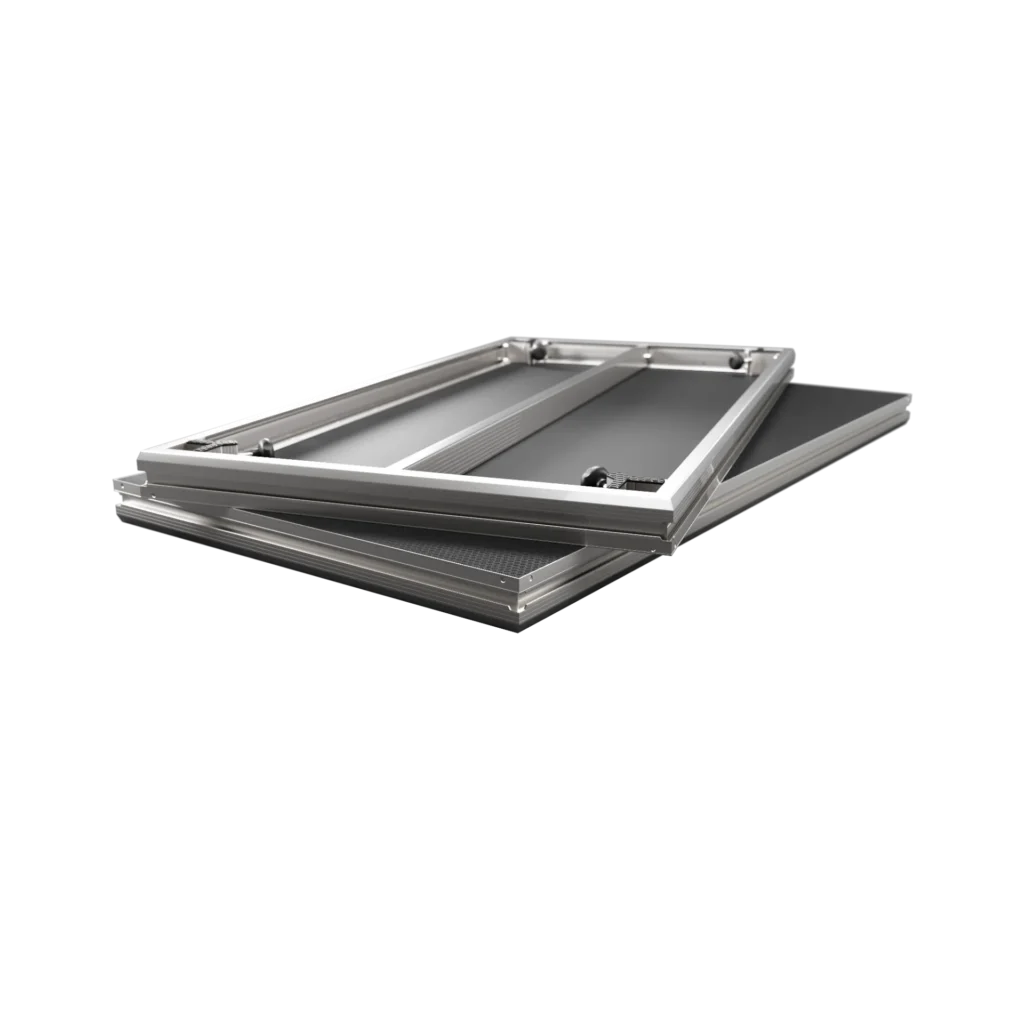

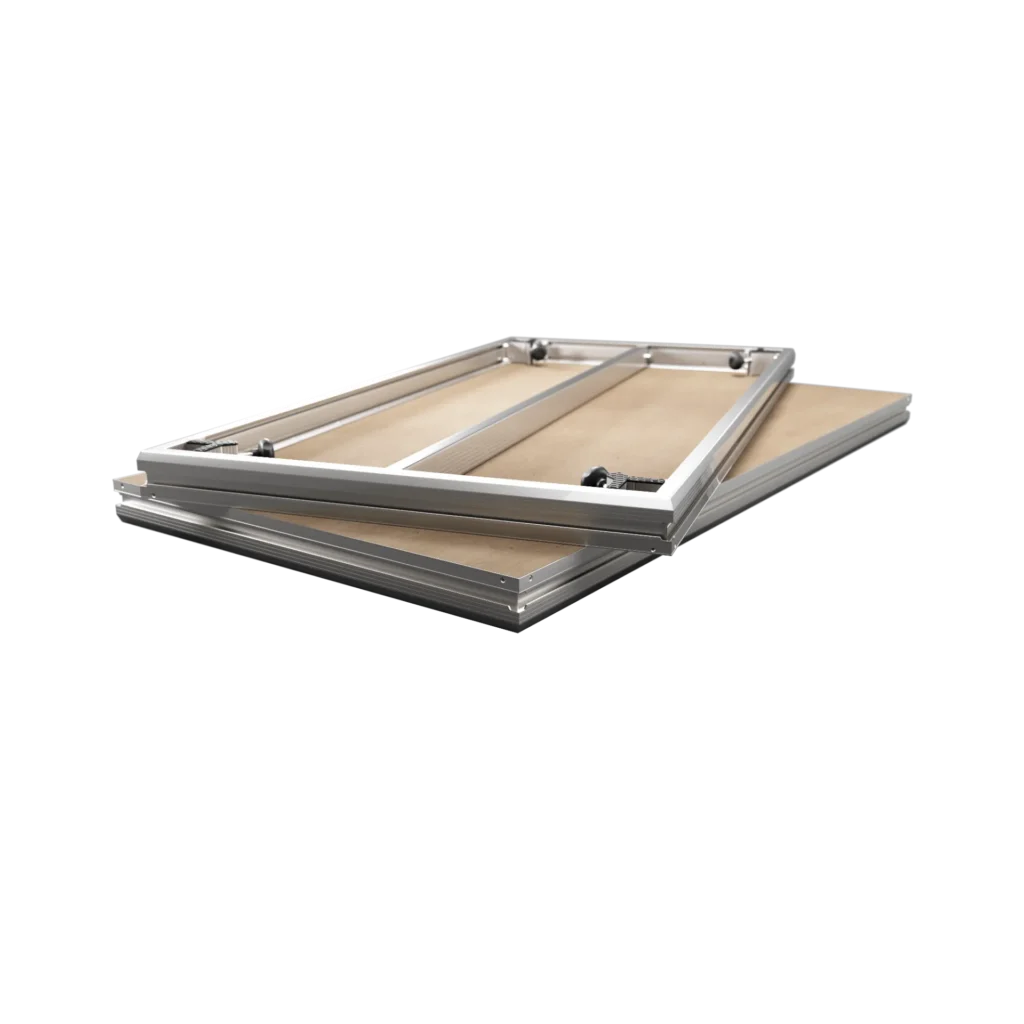

2. Full Customization — Your Product, Your Rules

We understand the importance of visual and functional consistency with your brand identity and specific application. That’s why we offer extensive customization options to enhance both the usability and aesthetic appeal of our products:

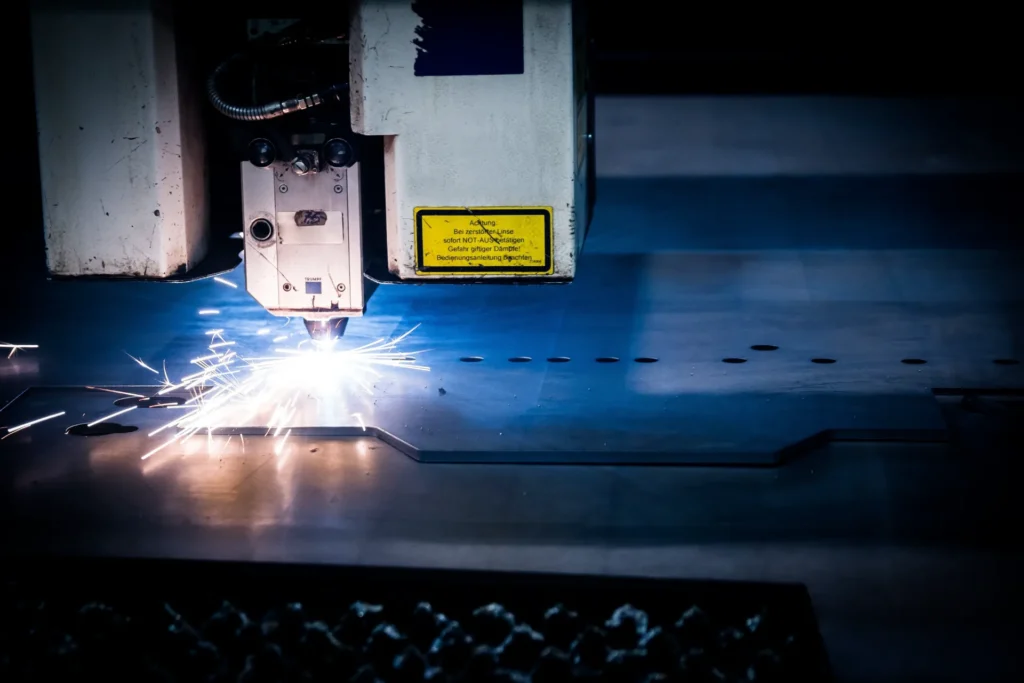

3. Precision Laser Cutting — Perfectly Matched Components

Your products are flawlessly prepared right from the cutting stage. With advanced 3D and 2D laser technology, we can:

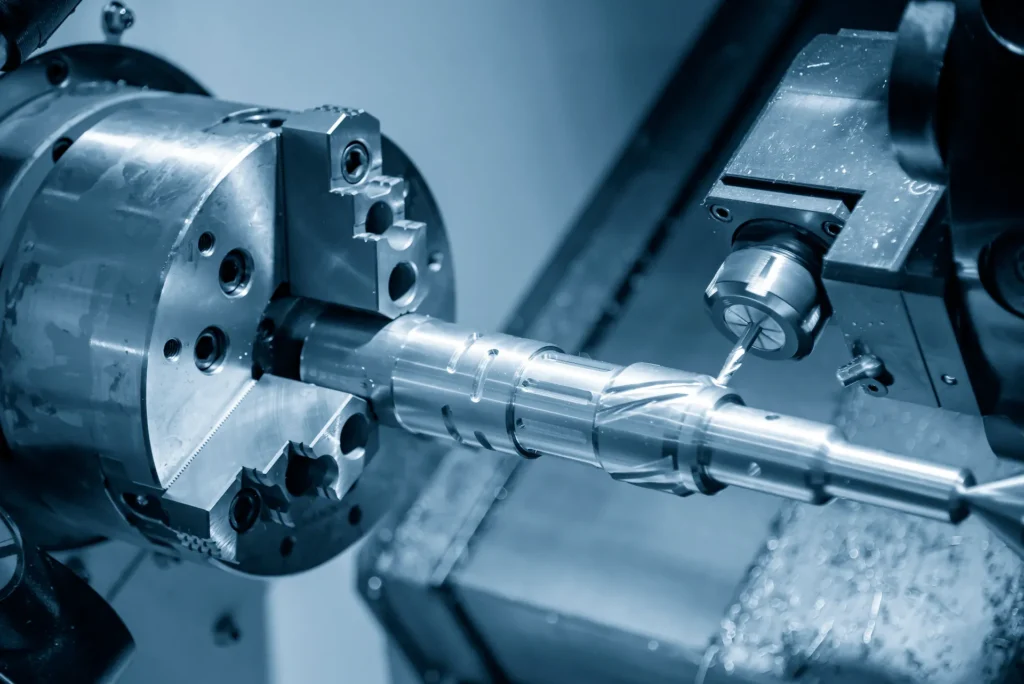

4. CNC & Multi-Axis Machining — Precision and Design Freedom

When your project demands complex shapes or high precision, we offer:

5. Sheet and Tube Bending — Form Meets Function

Our automated cutting and bending systems enable the creation of custom structures and complex shapes with highest precision.

No matter the technology, you can count on welds that are strong, clean, and built to withstand intensive use.

6. High-Quality Welds — Strength and Aesthetics of Every Structure

Our robotic welding systems deliver consistent, top-quality welds that enhance the durability of your structures. By using a variety of welding methods, we tailor the joining process to meet your specific needs:

7. Stamping and Punching — Fast and Precise Component Preparation

If your project requires serial perforation, embossing, or technical preparation of parts, we’ve got you covered:

Enjoy a premium visual effect that stands up to heavy use, both outdoors and in demanding environments.

8. Powder Coating — Durable, Weather-Resistant, and Aesthetically Superior Finishes

Your products can be finished in our automated powder coating facility, which offers:

9. Precision Fabric Cutting and Soft Component Manufacturing — Perfectly Matched to Your Structures

With our in-house sewing facility and advanced fabric cutting systems, we produce:

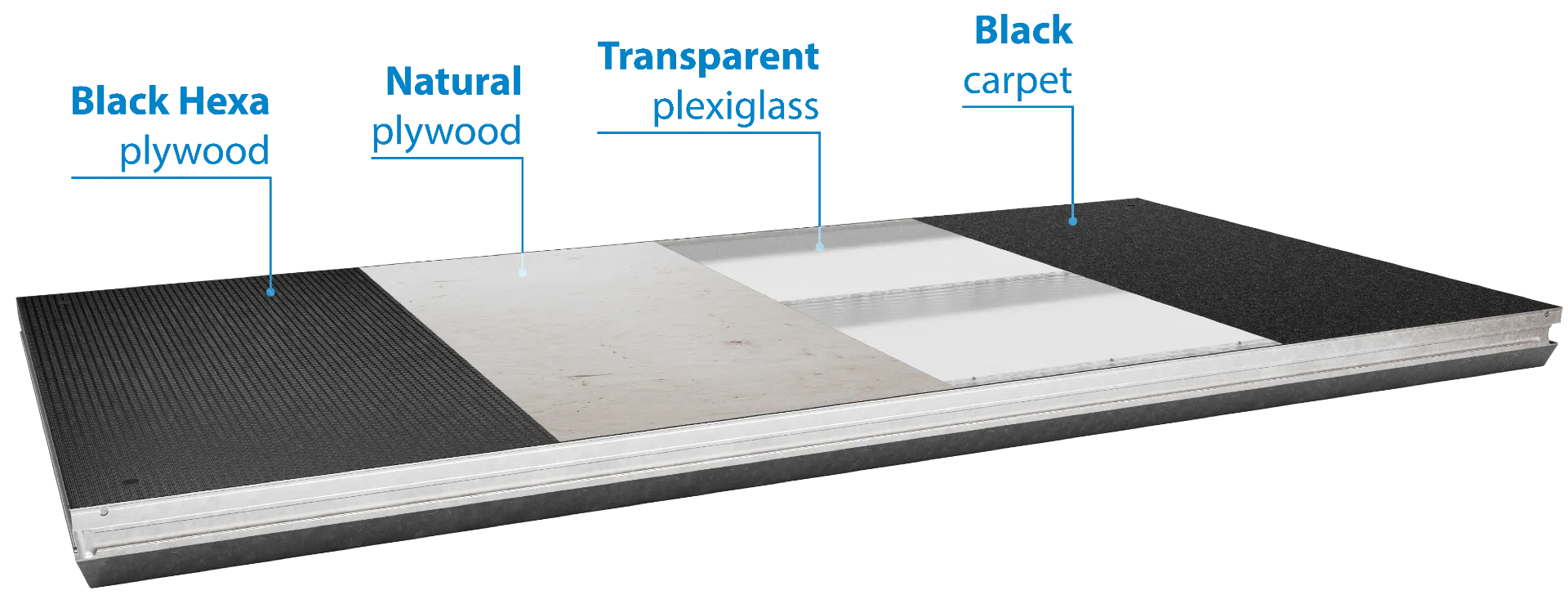

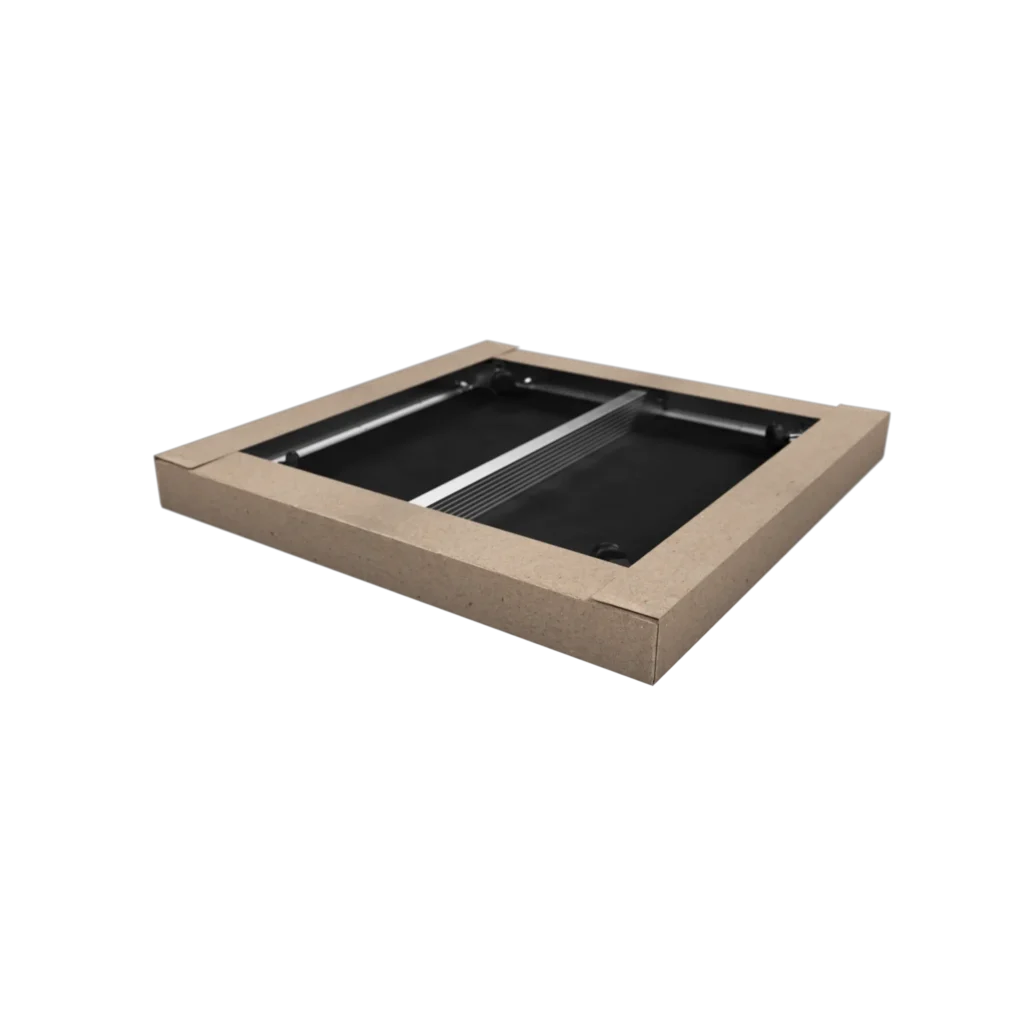

10. Wood, Under Full Control — Milling and Cutting Without Compromise

We offer precision machining of wood-based panels and plywood — fast, accurate, and with impeccable finish. Our services include:

ALUSTAGE – A TRUSTWORTHY COMPANY

Comprehensive Production — From Raw Material to Finished Product

We manage the entire process for you — from design, cutting, and machining, through welding

and painting, all the way to final assembly preparation. By partnering with us, you gain:

Whether you need a single custom component or full-scale

production runs, we deliver fast, precise, and complete solutions.

Get in touch with us and discover how we can bring your vision to life!

ALUSTAGE IN NUMBERS

WHY CHOOSE US?

Long-term business partnerships

We support clients worldwide, building stable and lasting relationships.

Spare parts and service support

We guarantee continuous availability of spare parts and comprehensive service, ensuring the reliability of our products.

100% Polish production

Full control over the process, delivering top quality and on-time execution.

30 years of experience

Our expertise and innovative approach make us an industry leader.

Full compatibility

Our products comply with international standards, allowing seamless integration with stage systems.

Fast order fulfillment

Our optimized production processes and efficient logistics ensure short lead times.

What can we do for you?

CONTACT ALUSTAGE

Get in touch with us!

Have questions? Interested in ordering Alustage products or creating

your own unique solution with us? Reach out — together, we’ll bring your vision to life!